IJmuiden, The Netherlands – MOTAS Dredging Solutions has supplied concept and detailed design services for the dredging installation including hardware.

Brice Civil Constructors is the operator of the dredge, which is currently in operation and doing extensive agitation dredging in the Atchafalaya River near Morgan City in the USA.

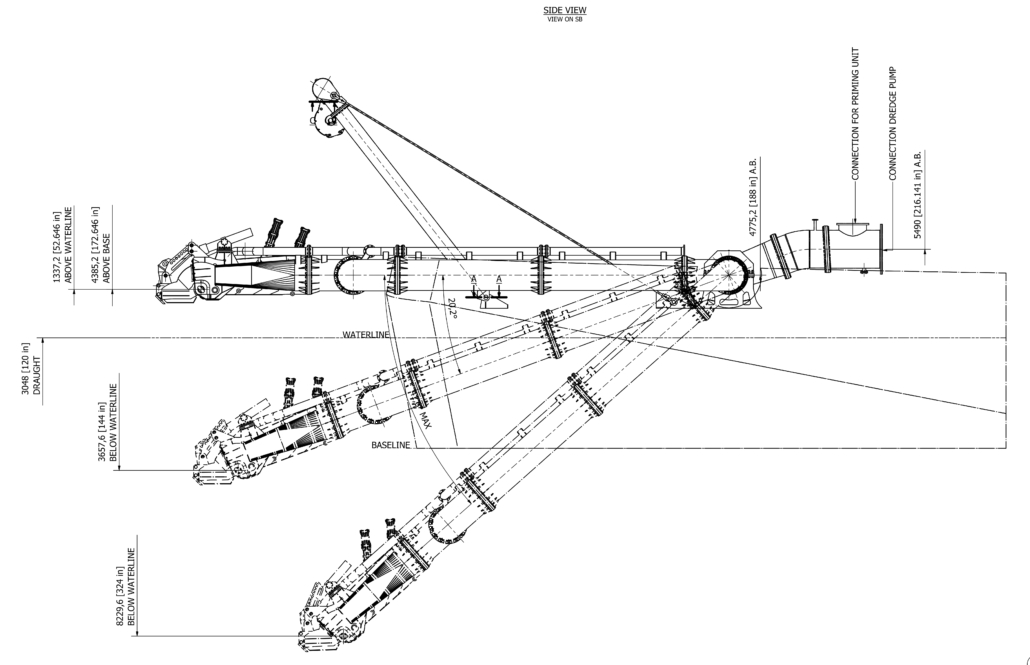

The concept was to mount a large dredge pump with two drag arms on the deck of an Offshore Supply Vessel. Rather than pumping material into the hold of a hopper dredge, the vessel would pump the material back overboard. The whole dredging process being assisted by a powerful jetwater system.

The currents in the river will then carry the agitated material further downstream. The whole dredge agitation process is repeated and the river will be opened up and can be maintained at navigational depths for vessels to reach berthing facilities upstream.

The Offshore Supply Vessel “M/V Capt John A. Graham” was selected to be the platform for the whole dredging installation.. The shipyard where the conversion took place was Halimar Shipyard in Morgan City.

We supplied the concept & detailed design services and hardware of the dredging installation.

Together with our partner Hagler Systems, the whole dredging installation was supplied to the shipyard, assembled and installed onboard.

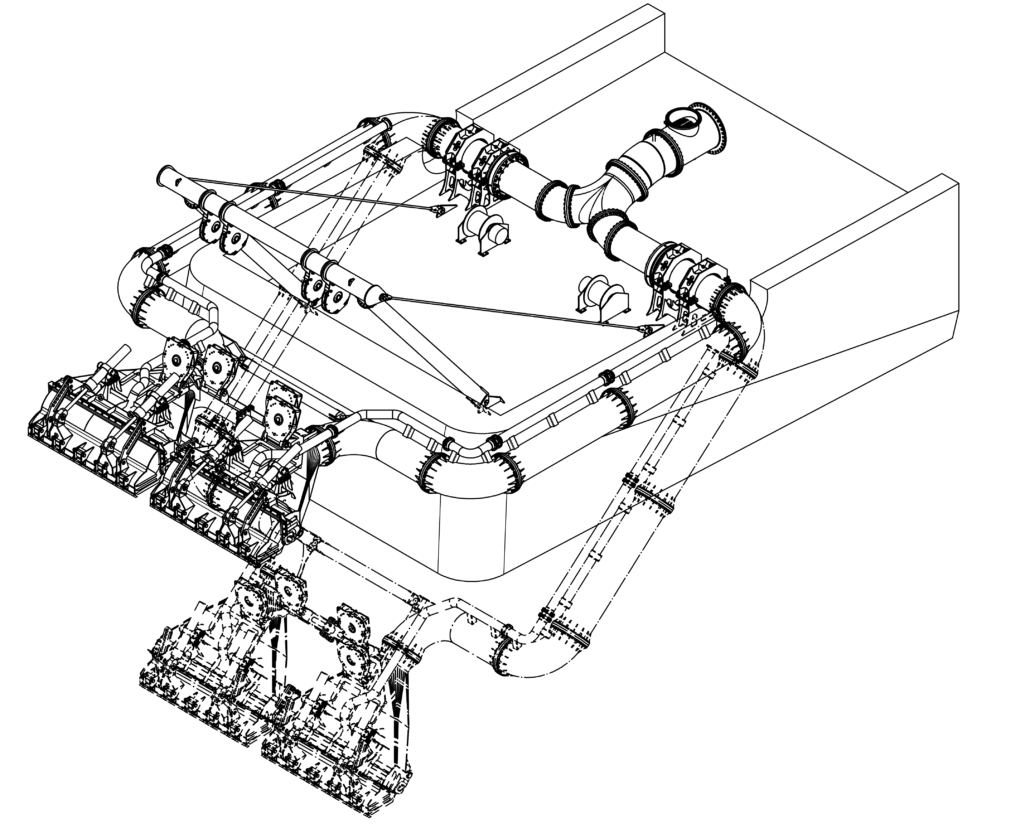

Hardware supplied together with our partner Hagler Systems:

- The dredge pump

- Two dragheads with jetwater provision in the heel and adjustable visor

- The dredge arm

- The Turning glands

- Dredge pipes

- The gantries with several sheave blocks

- The winches

- Hydraulic installation and the Hydraulic Power Pack (HPU)

- The pump inspection piece

Significant cost savings

“We had mechanical challenges we had to overcome” said Brice Civil Constructors, “but we’ve been pumping now for nearly a year. The average volume we’ve pumped on a month-to-month basis is about 5 million cubic yards per month.

The cost savings measured per cubic yard of material pumped are significant compared to cutterhead and hopper rates.

What’s more, the system is working. Since the dredge hit its stride toward the start of the year, the dredge has been exceeding its target and steadily deepening the bar channel to a navigable depth.