Custom made Fall Pipe System for Rohde Nielsen’s Grane R

IJmuiden- The Netherlands, On the 10th of September Rohde Nielsen inaugurated DP2 fall pipe rock installation vessel Grane R in a name giving ceremony.

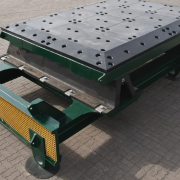

MOTAS dredging solutions designed, built, engineered, and installed the custom-made Fall Pipe installation in close cooperation with Rohde Nielsen. It will be used to accurately lay foundations on the seabed for offshore structures such as offshore windmills or to cover underwater trenches in which cables are placed. Due to the limited space on board of the Grane R the engineers of MOTAS had to work with every available m² of space. Therefore they integrated the Fall Pipe System in such a way that it takes up very little place when stored on board. The Fall Pipe System, when retracted, can be stored on the side deck of the ship.

Telescopic pipe and active motion compensation

The system is outfitted with a telescopic pipe extendable 0-10 meters, for flexibility. Due to the telescopic pipe, the Grane R can install rock accurately up to a depth of 60 meters. The telescopic section of the pipe can be operated via a computer which is located on board of the Grane R. Another feature that MOTAS engineered is the active motion compensation system. This system makes it possible to keep the pipe near-static positioned, even when it is being operated in rough seas. This combination of systems makes the Fall Pipe System very accurate when it comes to installing rock.

Turnkey delivery

MOTAS dredging solutions engineered, built and delivered the complete Fall Pipe System to Rohde Nielsen. The project was done in close cooperation with the client, resulting in a turnkey delivery. Offering turnkey solutions in this way is an important distinction of MOTAS Dredging Solutions.

Specifications for this project

- Rock capacity: 4900 t – option to increase

- Fall pipe size: Ø 1200 mm

- Max. rock size: 400 mm

- Fall pipe operational depth: 8-60 m – options for additional depth