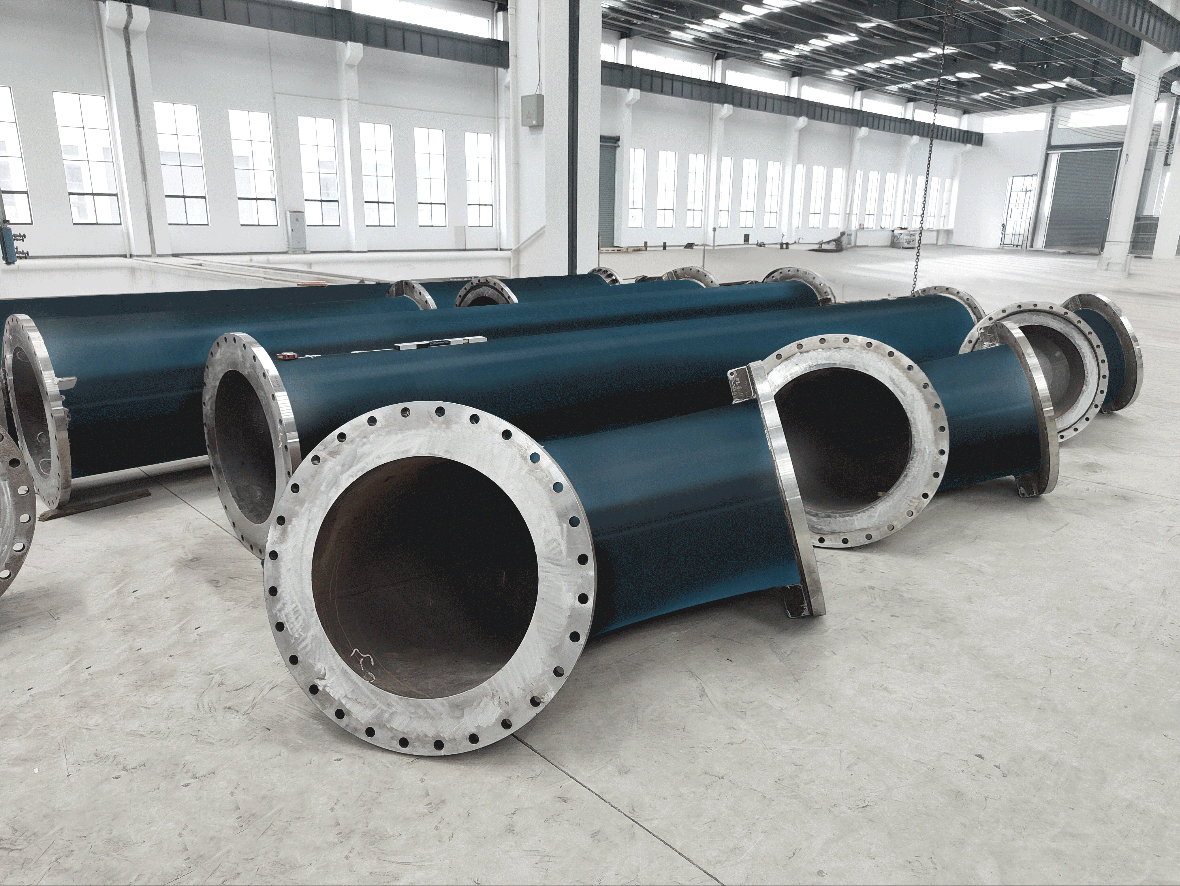

IJmuiden, The Netherlands – MOTAS Dredging Solutions has recently delivered its custom-designed suction pipe gantries to the shipyard, ready for integration into the new Trailing Suction Hopper Dredger (TSHD) currently under construction.

Customer assistance

Our comprehensive product portfolio, expert technical advice, and on-site support make us the ideal partner for all your dredging installation needs. Our team is ready to assist you in selecting the best equipment for your project and advise you on optimizations. Contact us at +31 85 13 00 795 or info@motas.group

About MOTAS Dredging Solutions

“MOTAS Dredging Solutions serves customers world-wide with the development, design and construction of dredging equipment, wear parts and systems.”

https://motasdredgingsolutions.com

Keywords:

- Trailing suction hopper dredger

- Dredge installation components

- Gantries

- Suction pipe gantries

- Customised

- Engineering

- Supply

- Engineered solutions