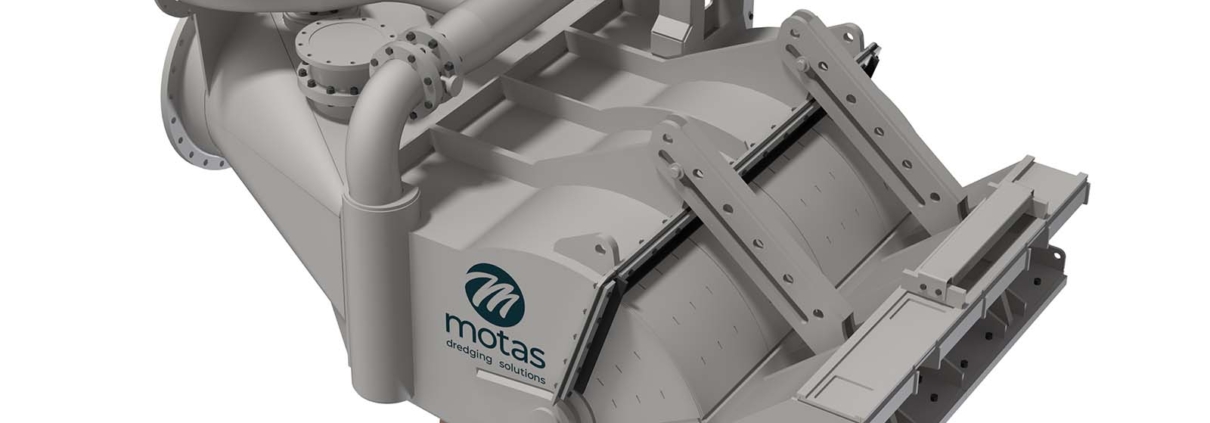

MOTAS delivers two dragheads to DC Dredging

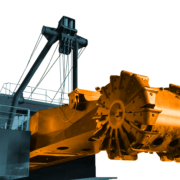

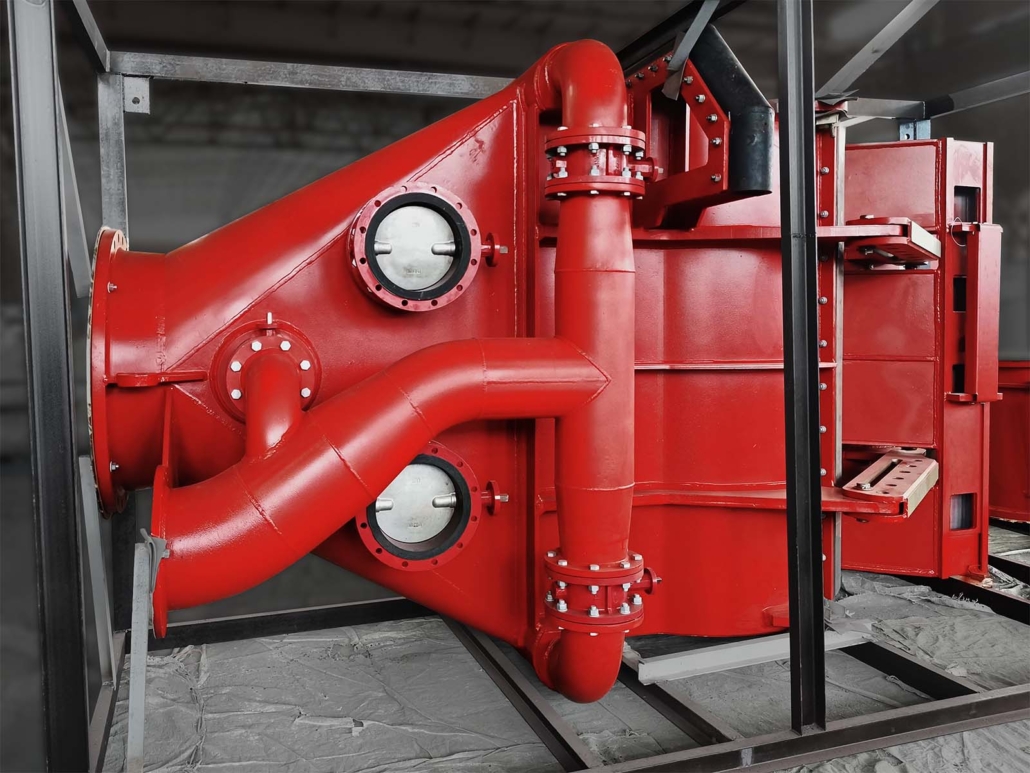

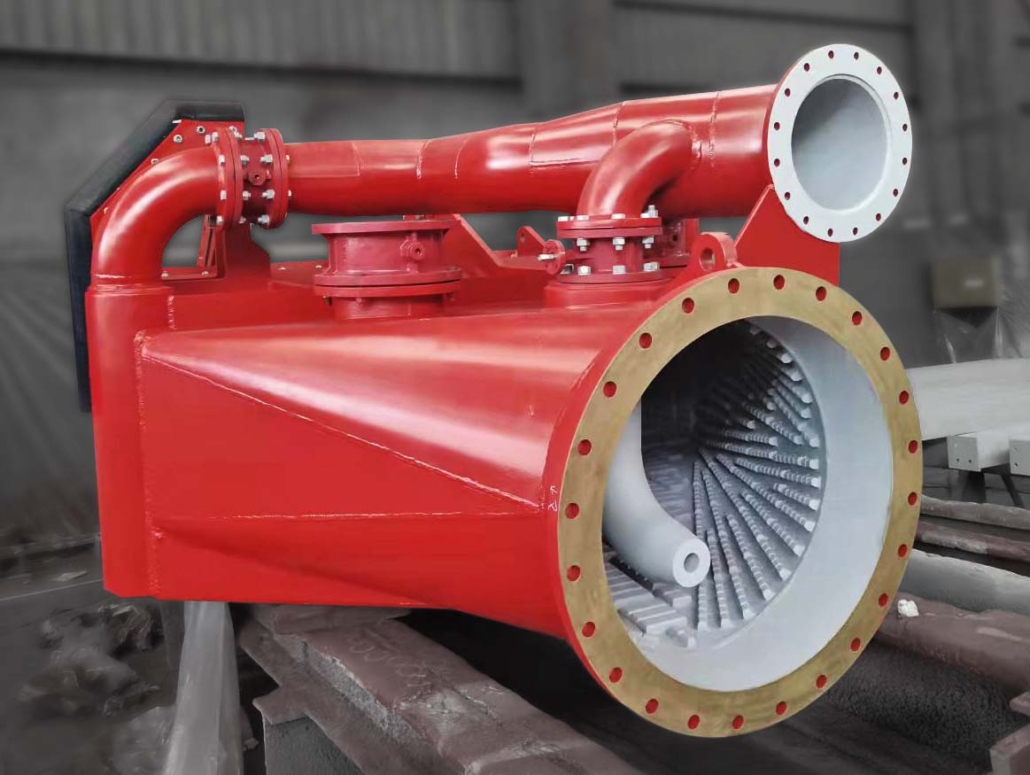

For customer DC Dredging, MOTAS Dredging Solutions produced two dragheads, which will be installed on the sand & gravel dredgers DC Ostend and DC Brugge.

Both dragheads will be used to dredge sand and gravel offshore at concessions in the North Sea.

Specifications

The draghead visors are fitted with knife plates, which are able to cut effectively into the soil. Furthermore both dragheads are fitted with jetwater nozzles in the heel plates. These nozzles inject water into the sand, which expands and loosens it before being dredged up. Internally, the dragheads are lined with so called “chocky bars”. These wear resistant tiles protect the draghead from excessive wear when dredging abrasive sands and gravels.

The production

The dragheads were fabricated by a co-maker under the supervision and following the QC procedures of a dedicated local MOTAS production manager. Having a dedicated production manager is of paramount importance for MOTAS, since this enables us to ensure high quality end products independent of the co-maker.

The dragheads were delivered on time and within budget.

Short specifications:

Draghead TSHD “DC Ostend”

- Suction diameter : 850mm

- Total weight : approx. 8 ton

- Width : approx. 2.5 m

- Excavating knifes : YES

- Jetwater through heel : YES

- Chocky blocks : internally lined

Draghead TSHD “DC Brugge”

- Suction diameter : 600mm

- Total weight : approx.. 6 ton

- Width : approx. 2.4 m

- Excavating knifes : YES

- Jetwater through heel : YES

- Chocky blocks : internally lined

Keywords:

- Sand & gravel dredging

- Knife plates

- Jetwater nozzles in heel

- Wear resistant chocky bars

- Heavy duty

- Trailing suction hopper dredger (TSHD)

f